Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

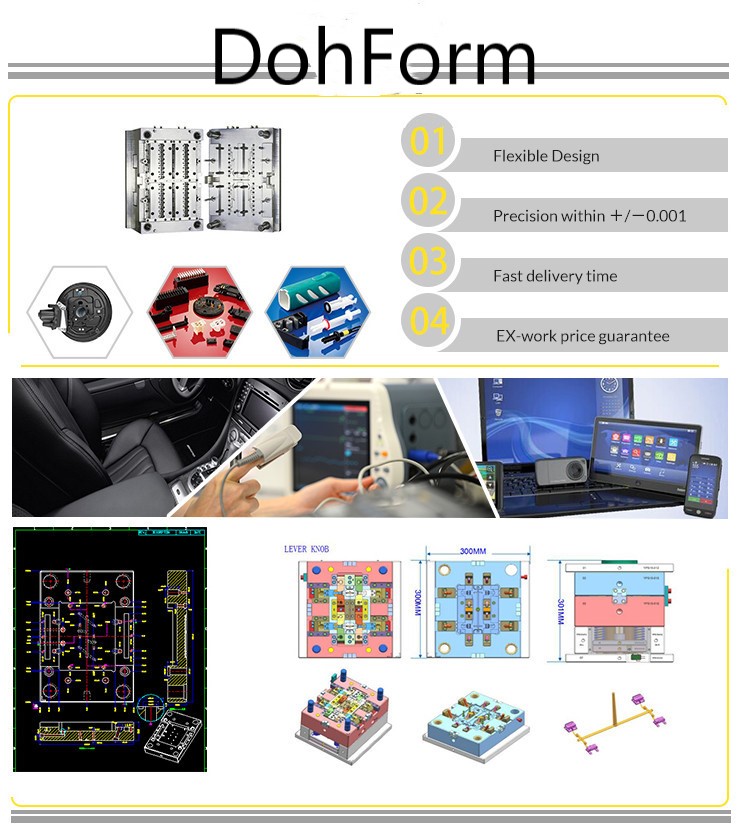

marchio: DoHform

Luogo D'origine: Cina

Metodo Di Formazione: Stampo di iniezione di plastica

Materiale Del Prodotto: Gomma da cancellare, Plastica

Prodotto: Muffa del veicolo, Apparecchio domestico, Prodotto domestico

Pacchetto: Scatola di legno esportata standard imballata, processo di fumigazione (su richiesta)

Trasporti: Ocean,Land,Air

Luogo di origine: Kunshan, Cina

Porta: Shanghai,Ningbo,China

Tipo di pagamento: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF,EXW

Parti in plastica stampate ad iniezione in abs per elettrodomestici

PRODUZIONE - STAMPAGGIO AD INIEZIONE DI PLASTICA

Attraverso la personalizzazione dello stampaggio a iniezione, produciamo stampaggio a iniezione di materie plastiche di tutti i tipi di prodotti industriali, siamo in grado di ridurre i tempi di fermo e fornire rapidamente tutti i tipi di parti personalizzate per stampaggio a iniezione di chiunque altro nel settore. Ciò significa che puoi lavorare in modo rapido ed efficace, portare avanti il tuo progetto. Consegna: immetti rapidamente i tuoi prodotti sul mercato

|

Product name |

Home appliance plastic parts,abs injection molded plastic parts |

|

Plastic material |

PP, PPA, ABS, PE, PC, POM, HDPE, etc. |

|

Steel of cavity and core |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: SCHMOLZ: P20HH, 2738, 2083H,2343, 2344, etc. DIN: 1.2738,1.2083, 1.2343, 1.2344, 1.3343, etc. AISI: P20, H13, D2, D6, M2, etc. ASSAB: 718HH, Nimax, 8402, 8407, XW-10, XW-5, EM2, etc. Japanese: HPM2, NAK80, SKD61, SKS3, SKD11, DC53, SKH51, etc. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Runner |

1.Hot Runner: (Synventive from Netherland) or as your requests. 2.Cold Runner. |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 1. 300,000-500,000 shots for 1 year under normal use prodcedure for pre-hardness steel material. 2. 5.00,000 shots for 1 year under normal use prodcedure for heat treatment steel material. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system). |

|

Production |

Pilot Run production and molding production can be provided. |

Elenco prodotti : Parti di ricambio di stampo > Pavoni di ricambio stampo sodick Machining Sodick Massino

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.