Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

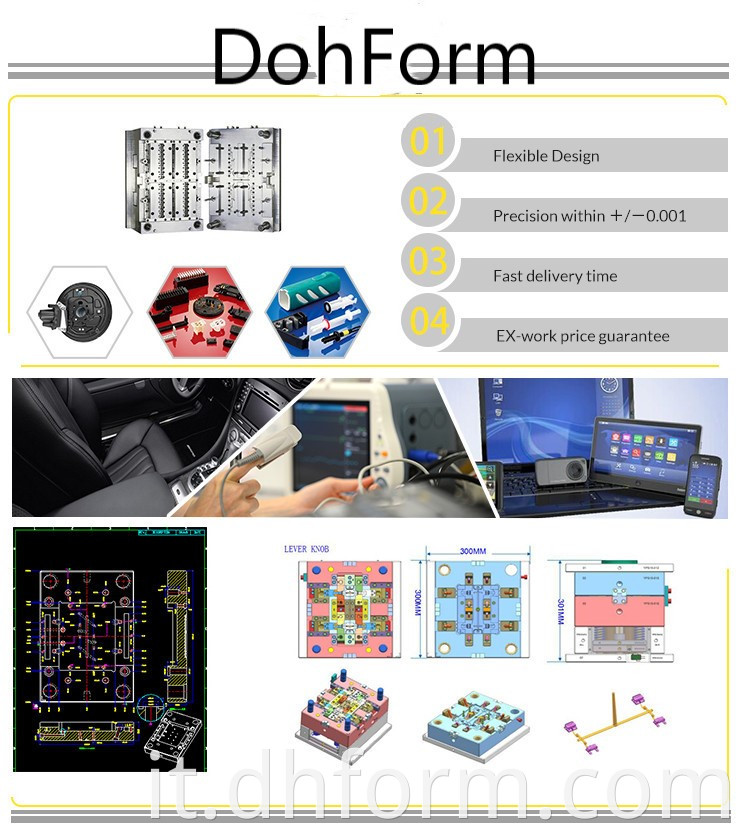

marchio: DoHform

Metodo Di Formazione: Stampo di iniezione di plastica

Materiale Del Prodotto: Gomma da cancellare, Plastica

Prodotto: Muffa del veicolo, Apparecchio domestico, Prodotto domestico

Luogo D'origine: Cina

Pacchetto: Scatola di legno esportata standard imballata, processo di fumigazione (su richiesta)

Trasporti: Ocean,Land,Air

Luogo di origine: Kunshan, Cina

Porta: Shanghai,Ningbo,China

Tipo di pagamento: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF,EXW

Fabbricazione di stampi medici per iniezione plastica OEM professionale

La fabbrica di stampi DohForm (Cina) è un esperto di soluzioni e un'azienda di stampaggio a iniezione di materie plastiche personalizzata. Produce principalmente forniture mediche, e-book, auricolari Bluetooth, audio, sicurezza, prodotti per serrature intelligenti e parti in plastica

Spedizione dello stampo 1. Testare lo stampo prima della spedizione

2. Ispezione della muffa, scattare foto della muffa

3. Pezzi di ricambio, disegni dello stampo imballati insieme allo stampo in scatola di legno

Progettazione disegno stampo 2D + 3D:

|

Product name |

Custom precision medical equipment plastic syringe injection mold |

|

Plastic material |

PP, PPA, ABS, PE, PC, POM, HDPE, etc. |

|

Steel of cavity and core |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: SCHMOLZ: P20HH, 2738, 2083H,2343, 2344, etc. DIN: 1.2738,1.2083, 1.2343, 1.2344, 1.3343, etc. AISI: P20, H13, D2, D6, M2, etc. ASSAB: 718HH, Nimax, 8402, 8407, XW-10, XW-5, EM2, etc. Japanese: HPM2, NAK80, SKD61, SKS3, SKD11, DC53, SKH51, etc. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Runner |

1.Hot Runner: (Synventive from Netherland) or as your requests. 2.Cold Runner. |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 1. 300,000-500,000 shots for 1 year under normal use prodcedure for pre-hardness steel material. 2. 5.00,000 shots for 1 year under normal use prodcedure for heat treatment steel material. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system). |

|

Production |

Pilot Run production and molding production can be provided. |

Flusso del prodotto

Come personalizzare uno stampo?

A) Prima del servizio di vendita

B) Servizio del periodo di produzione

C) Servizio post vendita

Il nostro partner

Confronto stampo

Elenco prodotti : Stampo per iniezione plastica > Stampa di parti mediche di plastica

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.